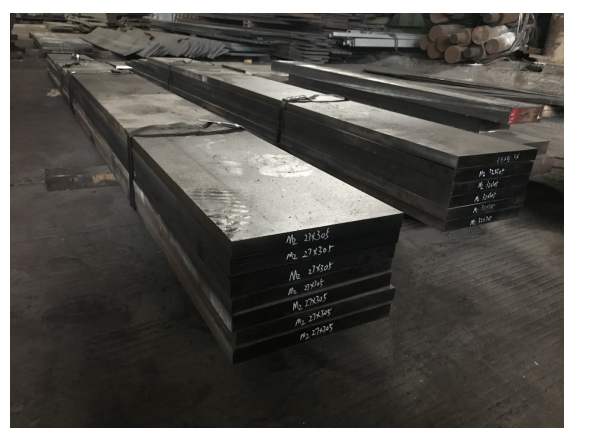

M2 high-speed steel processing and processing:

M2 high-speed steel annealing: the holding time should be more than 3~4 hours, after the heat preservation, it can be cooled to below 500°C at a rate of 10~20°C/hour, or it can be cooled to 740~760°C and stay for 4~6 hours , Isothermal annealing method after cooling to below 600°C.

M2 high-speed steel quenching: due to high alloy content, poor thermal conductivity, heating too fast and easy to crack, so 1-3 preheating during quenching.

M2 high-speed steel temperature preheating: 450~500°C, heat preservation 1-1.5min/mm, air furnace;

M2 high-speed steel medium temperature preheating: 800~850°C (more at 800~820°C), heat preservation 0.4~1.0min/mm, salt bath furnace;

High temperature preheating of M2 high-speed steel: 1050~1100°C, the time is the same as the quenching time;

General tools can use a medium temperature preheating (preheating time is twice the heating time), complex shape or large use low and medium temperature preheating 2 times, there are also 3 times preheating. But high temperature preheating can shorten the holding time of quenching.

M2 high-speed steel tempering: simple tempering for 2 tempers, complex shape for 3 tempers, even 4 tempers.

Low temperature tempering method: one tempering at 320~380°C, then the second and third tempering at 560°C.

The same temperature method: that is all tempered at 560°C (each time basically 1 hour).

Decarburized layer:

The depth of the decarburized layer (ferrite + transition layer) on each side of M2 high-speed steel is:

Hot rolled or forged steel: ≤(0.3~0.4)+(1~1.3)%D;

Cold drawn steel ≤(1~1.3)%D;

The role of forging:

After hot rolling of as-cast M2 high-speed steel, the grains and carbides are coarse and uneven, so it needs to be improved by forging.

Forging can make the metal structure broken by external force. The greater the amount of forging deformation, the better the uniformity of the broken carbide.

Generally, it is required to repeatedly upset and lengthen precision large-scale cutting tools, and the forging ratio is between 7 and 11.